Pallet Flow Racks

Pallet racking systems are an integral part of Logistics and have become the prevalent system for storing goods. These systems are suitable for medium to heavy loads, where the material to be stored is palletized and placed on racks. Pallet systems consist of vertical uprights and horizontal load beams which are specifically designed for the loads being stored.

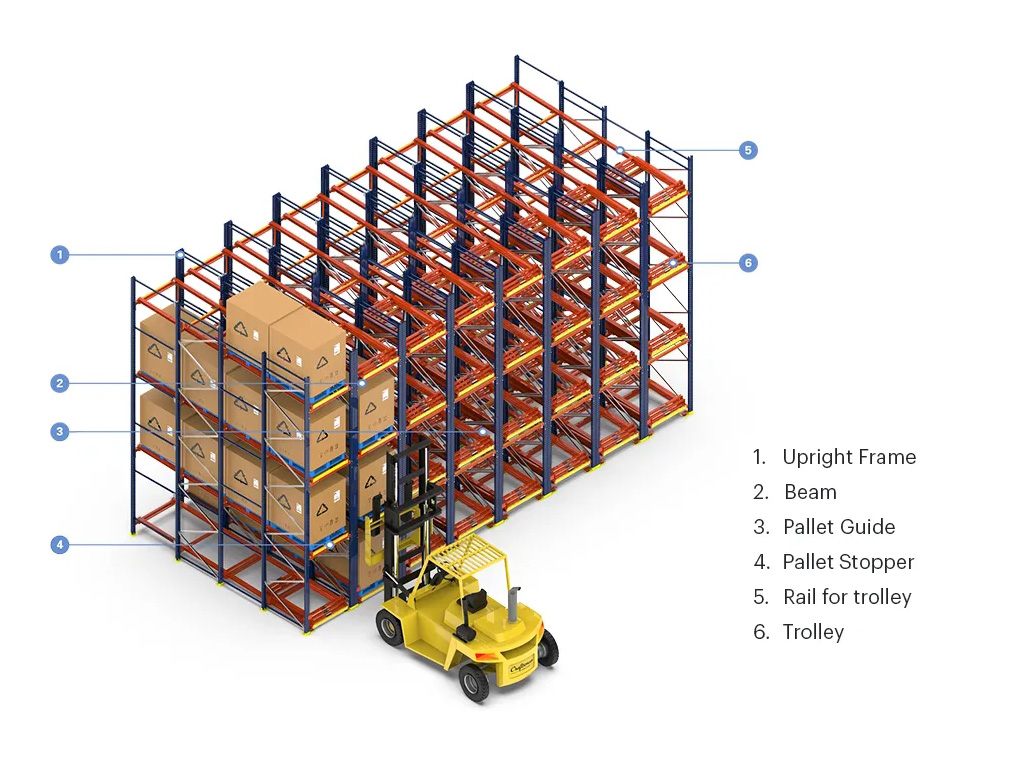

Push Back Racking

When it comes to storing the same SKU at pallet level with medium density, push-back racking is one of the preferred options. Last-In-First-Out (LIFO) is used with push-back pallet racking, which saves space.

Also, push-back pallet racking systems are appropriate for holding several pallets of the same SKU. All our pallet lanes operate independently, thereby offering a flexible and dense pallet storage option. Once a pallet is unloaded on our systems, the remaining inventory replaces the position of the front pallet by a sliding cart that utilizes gravity, ensuring the uninterrupted availability of a pallet in picking faces. Our push-back pallet racking system can be accessed with all major types of forklifts, including counterbalance, narrow-aisle, and swing reach lifts. Also, they are compatible with an extensive range of accessories such as collision protection, MHE stopper, etc.

Provides more storage rack area with a single-aisle design

Low Maintenance Cost

Designed for safe operation

Allows for quicker and easier loading/unloading of pallets

- Offers better use of available space than most systems

- Allows increased storage of SKU’s

- Allows for quicker and easier loading/unloading of pallets

- Saves on labor and labour risks by avoiding both the removal of obstructive pallets by forklift drivers and direct entry of employees channels for goods retrieval

- Minimizes honeycombing effect in the warehouse

- Provides more storage rack area with a single-aisle design

- Low-maintenance costs